Lead contamination in paint remains a serious public health issue in Bangladesh, with recent studies showing dangerously high levels in many decorative paints, though the government is now finalizing a national strategy to eliminate lead pollution. The Bangladesh Standards and Testing Institution (BSTI), UNICEF, Bangladesh Paint Manufacturer Association (BPMA), and NGOs like ESDO are actively pushing for updated standards and enforcement.

What is Lead?

Lead is a naturally occurring heavy metal, because its density is very high. Generally, metals that have a very high density are called ‘heavy metals’. These metals have a large metal density of 5 gcm³. The density of lead is about 11.34 grams per cubic centimeter and the atomic number is 82, which indicates a heavy element. And lead is not only heavy, it is a toxic metal that can harm the body and the environment. Lead is easily oxidized and forms various compounds, which are permanent in the environment. Therefore, due to its toxicity and weight, it is considered a dangerous heavy metal.

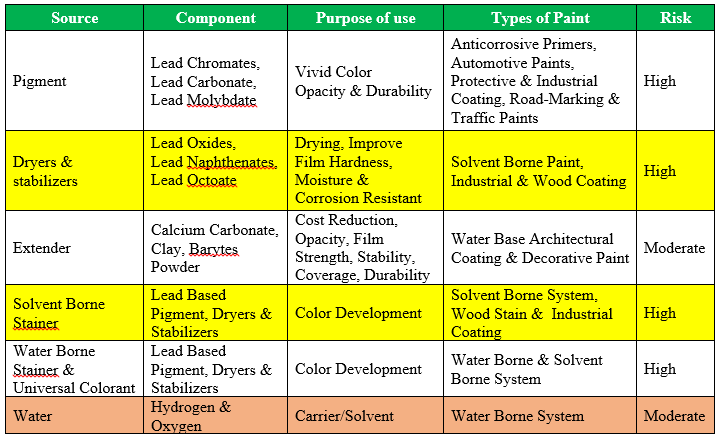

Lead Sources in Paint & Coatings:

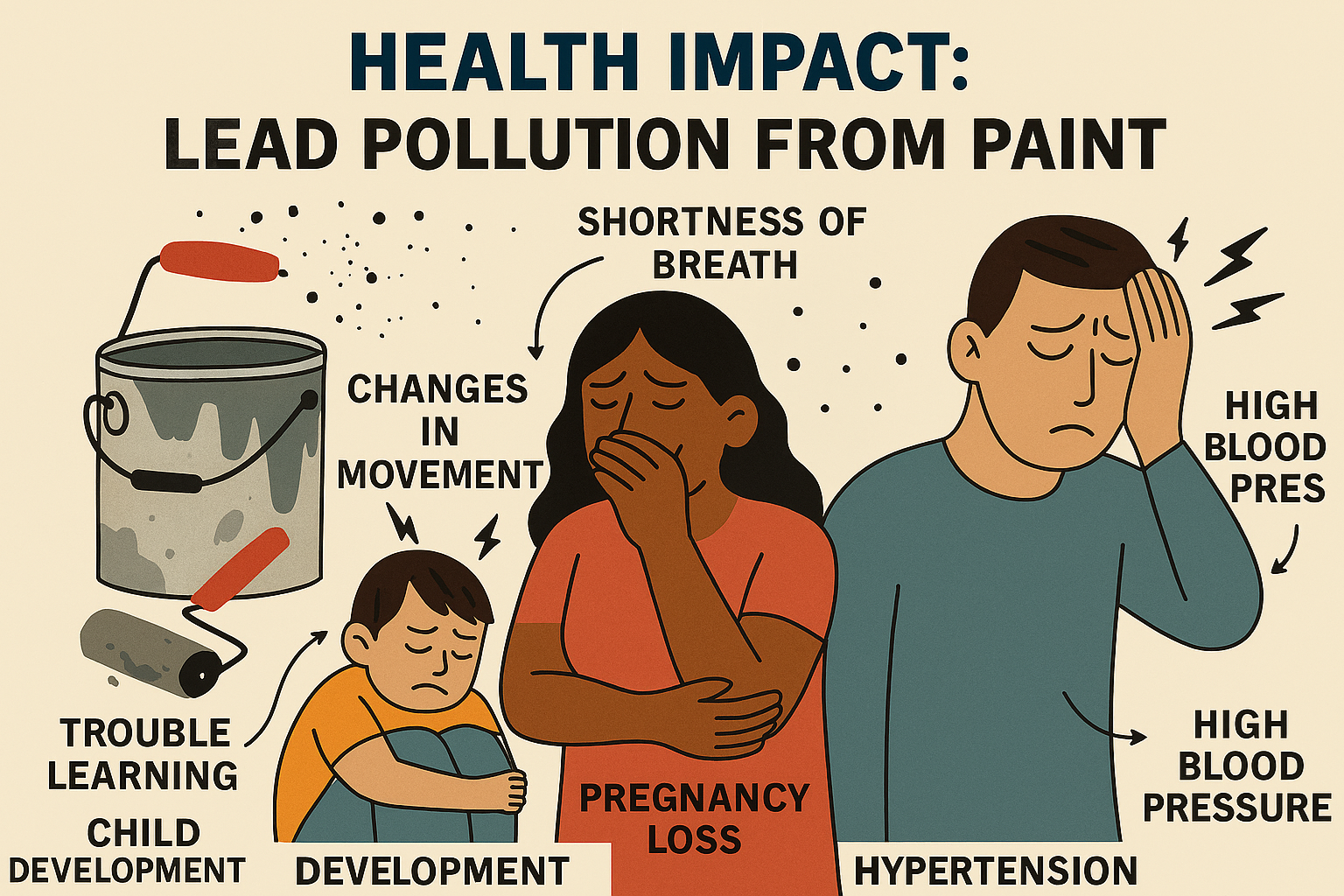

Health Impact:

Lead based paint film peels or cracks, it releases fine lead dust, which can easily enter the body with the breath. Breathing in this dust allows lead particles to enter the lungs and then the bloodstream. Lead is a systemic toxicant that impacts every organ in the human body, with its effects posing particularly severe risks to children and pregnant women. According to UNICEF and the Bangladesh Bureau of Statistics, the country indeed ranks 4th globally in terms of children affected by lead poisoning, with over 35 million children showing dangerously high lead levels in their blood.

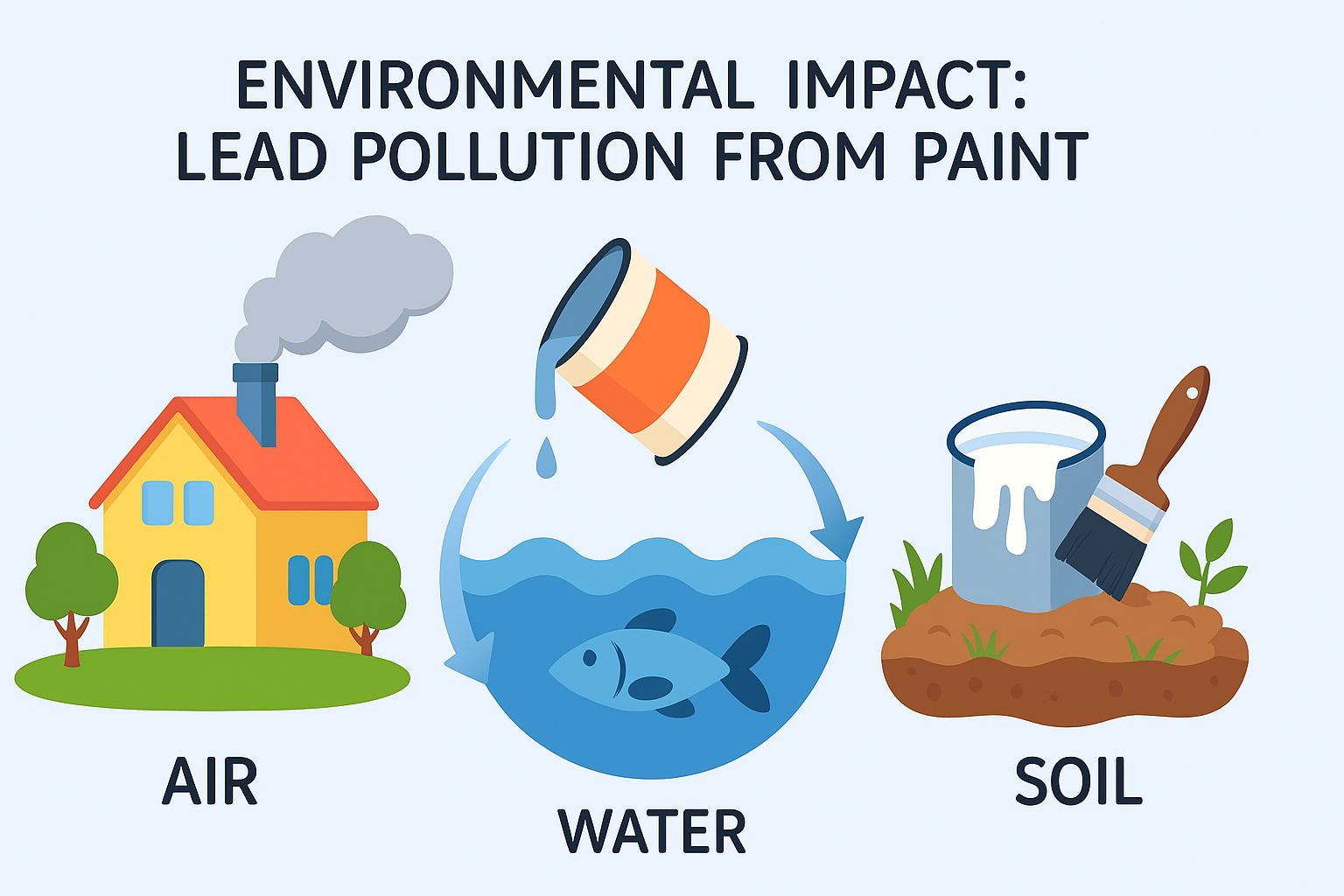

Environmental Impact:

Lead pollution from paint harms the environment by contaminating soil, water, and air. When lead-based paint deteriorates or is improperly removed, toxic particles settle into soil, wash into water bodies, and disperse through the air. This persistent contamination disrupts ecosystems, poisons wildlife, and enters the food chain—posing long-term risks to agriculture, biodiversity, and human health. Improper disposal of unused paint often leads to serious environmental damage, as it is commonly thrown on the ground or into water bodies. This practice should never be followed; instead, paint must always be disposed of in a safe and proper manner. Furthermore, old buildings or those repainted after long periods require careful maintenance. Cracked and deteriorating paint should be repainted promptly to prevent harmful lead dust from entering the air and posing risks to human health and the environment.

WHO and BSTI Guideline:

There is no safe level of lead exposure. Among various environmental pathways, lead-based paints are identified as a major contributors of lead contamination in homes and communities. The WHO, together with UNEP and the Global Alliance to Eliminate Lead Paint (GAELP), sets the recommended maximum lead content in paints at 90 ppm. Through S.R.O 221-Law/2018, the Bangladesh Standards and Testing Institution (BSTI) introduced a 90 ppm total lead limit setting standards for architectural coatings such as emulsion, latex, distemper, and enamel, in alignment with the WHO/UNEP Model Law. So far industrial, marine, automotive, wood, and specialized paints remain unregulated, and enforcement of the existing rule is limited. In this issue, Bangladesh Standards and Testing Institution (BSTI) developed three mandatory standards in 2018 (BDS 1423:2018, BDS 1827:2018, and BDS 1833:2018)

Critical Analysis of the ESDO Findings:

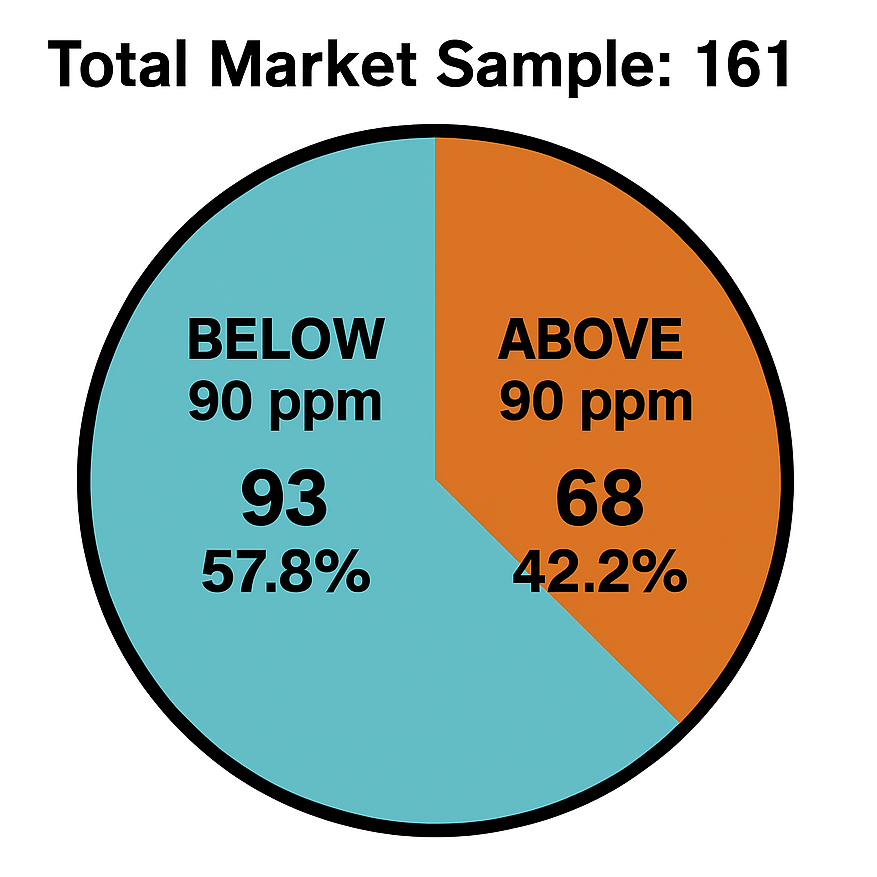

In 2025, the Environmental and Social Development Organization (ESDO) conducted a Lead Exposure Elimination Project to assess the presence of lead in household paints. A total of 161 paint samples were collected from Dhaka and Chattogram, encompassing both major paint brands and products from local manufacturers and imported sources. The study offers vital insights into the level of lead contamination in paints available in Bangladesh, emphasising public health risks and the urgent need for stronger regulation and increased consumer awareness.

The pie charts (Figure 01) show 42.2% of samples (68/161) exceeded the BSTI standard 90 ppm limit. Most of these were imported and produced by small-scale unregistered manufacturers who failed to maintain safety labeling, manufacturing address, certification marks, TDS, and MSDS. All leading brands (Berger, Asian, Nippon, Elite, etc.) comply with the 90 ppm limit, ensuring safety.

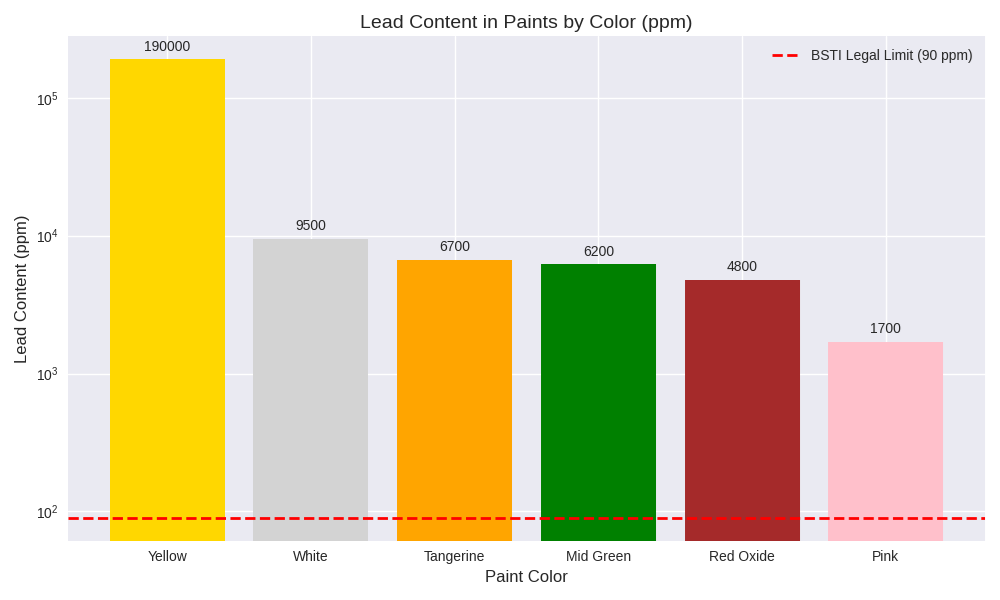

In Figure: 02, Kangaroo (Imported Brand) yellow paint was found to contain 190,000 ppm of lead—an alarming 2,111 times higher than the BSTI legal limit of 90 ppm. Other brands such as Jhumur (White: 9500 ppm), 777(Tangerine: 6700 ppm), Rauza (Mid Green: 6200 ppm), Anchor Premium (Red Oxide: 4800 ppm), and Penguin (Pink: 1700 ppm) show lead levels that are extremely high compared to the standard legal limit. All are solvent-based decorative paints except for Penguin, which is a spray paint. Bright shades such as Yellow, Red, Tangerine, and Green contain exponentially higher lead content compared to lighter tones. Yellow and orange paints are strongly associated with lead chromate pigments, while green and blue paints often contain lead oxide chromate. These pigments are commonly used in solvent-based formulations. Red paints typically contain lead molybdate pigments or employ lead dryers such as lead naphthenate, which are added to enhance vibrancy and durability.

Lead-Free Progress in Bangladesh’s Paint Sector: In Bangladesh’s rapidly growing paint industry, Berger Paints Bangladesh Ltd stands as the market leader, commanding more than half of the national market share. But beyond commercial dominance, Berger has positioned itself as a pioneer in sustainability and public health by eliminating lead from its paints and eco-friendly innovation. Berger Paints Bangladesh became the first company in the country to eliminate lead from all paints in 2011. Today, all of its water-based products and textile chemicals are formulated to be free from heavy metals, low in volatile organic compounds (VOC), and devoid of carcinogenic, mutagenic, and reproductive (CMR) substances. Looking ahead, Berger has set a clear sustainability target to make all water based products APEO-free by 2025. According to recent studies by the Environment and Social Development Organization (ESDO), several established companies—including Asian Paints, Nippon Paint, and Elite Paint—are maintaining compliance with the Bangladesh Standards and Testing Institution (BSTI) regulation that limits lead content in paints to 90 ppm. In contrast, imported paints and products from unregistered local manufacturers were found to contain dangerously high levels of lead, representing a serious violation of compliance and regulatory standards.

The tests were conducted using Inductively Coupled Plasma–Optical Emission Spectroscopy (ICP-OES), with a reporting limit of 49 ppm compared to the BSTI standard of 90 ppm. In contrast, third-party reports on Berger Paints showed that lead was not detected, with a reporting threshold as low as 10 ppm.

Test reports on Berger’s popular Easy Clean brand confirm that the product is completely lead-free, with no lead detected against a reporting limit of 10 ppm compared to the BSTI standard of 90 ppm. Moreover, Easy Clean is also free from all types of heavy metals, reinforcing Berger’s commitment to consumer safety and environmental responsibility. The company uses lead-free labeling across all of its products to promote consumer awareness and highlight its commitment to safety.

The ESDO report revealed that only 21.6% of paints tested (35 out of 162 samples) carried “Lead-Free” or “Eco-Friendly” labeling. Alarmingly, four of these paints were found to contain lead despite displaying a lead-free logo, highlighting serious gaps in compliance and misleading consumer practices.

When asked about this, Dr ASM Obaidullah Mahmud, Chief R&D Officer at Berger Paints Bangladesh Limited, said lead pollution from paints is a critical public health issue, particularly for children. At Berger Paints Bangladesh, we recognized this risk early and eliminated lead from all our formulations in 2011. Through advanced research and innovation, we replaced lead-based pigments and additives with safe alternatives that deliver the same durability and colour performance without toxicity. Our R&D strategy is clear—innovate safer alternatives, uphold strict quality standards, and collaborate with regulators and stakeholders to build a healthier, lead-free environment for future generations. Our team is committed to embedding climate resilience and green innovation into every product line, ensuring that paint is not just a coating but a contributor to healthier living spaces.

The Role of BSTI, BPMA, NGOs, and National/International Organization:

On July 3, 2018, the Bangladesh Standards and Testing Institution (BSTI) introduced a lead limit of 90 ppm for decorative paints, aligning the country with international standards. This was a landmark step toward protecting public health, particularly children, from the dangers of lead exposure. However, no regulatory limit has yet been set for industrial paints, leaving a significant gap in protection. Industrial paints, widely used in factories, construction, and infrastructure, continue to pose risks to workers and surrounding communities. To address this gap, the active participation of all stakeholders is essential. An executive committee already formed to establish a national policy for industrial paints, ensuring that regulations are comprehensive, inclusive, and effective in combating lead pollution.

Recognizing this urgent need, on November 25, 2025, a policy dialogue titled “Preventing Lead Poisoning and Updating Standards for Industrial Paints, Cookware, and Toys” was jointly organized by BSTI, UNICEF, and the Environment and Social Development Organization (ESDO). The event brought together government agencies, industry representatives, NGOs, and international partners to discuss strengthening standards, closing regulatory gaps, and advancing public health protections. BSTI should recommend that the government enact legislation with strict guidelines for all paint companies. These guidelines must include mandatory product testing, continuous market monitoring, compulsory labeling, and clearly defined maximum permissible limits for lead content. Such measures would ensure accountability across the industry. For a lead‑free and safe future, the Environment and Social Development Organization (ESDO) has consistently advanced international collaborations with UNICEF, UNEP, the European Union, the World Health Organization, IPEN, ILA, and GAELP. These partnerships highlight the power of collective action in tackling global health threats. The Bangladesh Paint Manufacturers Association (BPMA) should actively raise awareness among its members about the dangers of lead exposure and commit to a specific time frame for making all paints lead‑free. In addition, unregistered paint companies must be identified, and strict action should be taken against them to ensure accountability and protect public health.

Md. Mohsin Habib Chowdhury, President of the Bangladesh Paint Manufacturers Association (BPMA), stated that the association is committed to raising awareness among its members, setting clear timelines to make all paints lead‑free, and working closely with regulators to ensure strict compliance. He emphasized that, through responsible industry practices and strong enforcement, it is possible to protect children, safeguard communities, and build a healthier, lead‑free future.

Sk Emadul Bari is a dedicated researcher at Berger Paints Bangladesh Ltd, where he passionately contributes to the field of the paint and coating industry. He holds a master’s degree in applied chemistry and chemical engineering from the University of Rajshahi. An accomplished paint & coating research & development professional with over 18 years of proven experience in water-based coating innovations, paint formulation, and raw material selection with a strong focus on eco-friendly solutions and VOC reduction strategies.

His expertise extends to developing sustainable practices that enhance product performance and minimise environmental impact. With a track record of successful projects, he is committed to advancing the industry towards greener alternatives and setting new standards for quality and sustainability.

Views expressed in this article are the author’s own.